CNC Machining Services for Advanced Materials: Meeting EV and Aerospace Demands

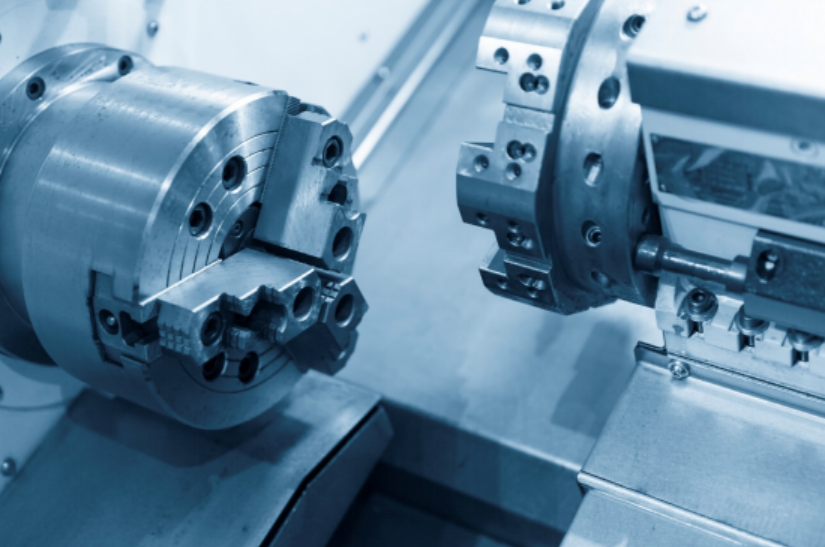

In a world racing toward innovation, where electric vehicles (EVs) hum down highways and aerospace giants push the boundaries of flight, one technology quietly powers their progress: CNC machining services. These precision-driven services are the unsung heroes behind the sleek battery housings of a Tesla and the intricate turbine blades of a Boeing jet. But as industries like EVs and aerospace demand ever-more complex materials—think titanium alloys, carbon fiber composites, and lightweight magnesium—traditional machining just won’t cut it. So, how are CNC machining services rising to the challenge? Let’s dive into the heart of this high-tech revolution, where precision meets possibility, and explore how CNC machining is shaping the future of advanced manufacturing.

The Growing Role of CNC Machining Services in EV and Aerospace Innovation

Picture this: a Tesla Model S zipping silently down the road, its lightweight aluminum battery housing keeping it efficient and safe. Or a next-generation satellite orbiting Earth, its magnesium alloy shell crafted to withstand cosmic extremes. These marvels rely on CNC machining services, which deliver the precision and versatility needed to shape advanced materials into game-changing components. The electric vehicle and aerospace industries are booming—global EV sales hit 14 million units in 2024, while aerospace spending is projected to reach $1 trillion by 2030. Both sectors demand parts that are lighter, stronger, and more complex than ever before, and CNC machining is their go-to solution.

Why? Because CNC (Computer Numerical Control) machining uses computer-guided tools to carve materials with pinpoint accuracy, often to tolerances as tight as 0.001 inches. This precision is critical when you’re crafting parts for EVs, where every gram saved boosts range, or for aerospace, where a single flaw could spell disaster. As these industries lean on materials like titanium, Inconel, and carbon fiber, CNC machining services are stepping up, blending cutting-edge tech with old-school craftsmanship to meet skyrocketing demand.

Why Advanced Materials Are Driving Demand for CNC Machining Services

Advanced materials are the backbone of modern EVs and aerospace systems. Aluminum and magnesium alloys make vehicles lighter, boosting EV range by up to 15%. Carbon fiber composites offer unmatched strength-to-weight ratios, critical for aircraft fuselages. Titanium and Inconel withstand extreme heat and stress, making them ideal for turbine blades and rocket components. But these materials aren’t easy to work with—they’re hard, brittle, or prone to cracking, posing unique challenges for manufacturers.

Enter CNC machining services. Unlike traditional methods, CNC machines can handle these materials with finesse, using multi-axis systems to carve complex shapes in a single setup. For example, five-axis CNC machines rotate tools and workpieces simultaneously, enabling intricate geometries that would stump older equipment. The result? Parts that meet the stringent demands of EV battery enclosures or aerospace structural components, all while reducing waste and production time.

Table 1: Advanced Materials in EV and Aerospace Applications

| Material | Industry | Key Application | CNC Machining Challenge | Benefit |

| Aluminum Alloy | EV | Battery Housings, Motor Casings | High thermal conductivity requires precise cooling | Lightweight, improves EV range |

| Carbon Fiber | Aerospace, EV | Fuselage Panels, Car Body Components | Brittle, requires specialized cutting tools | High strength-to-weight ratio |

| Titanium Alloy | Aerospace | Turbine Blades, Structural Frames | High hardness accelerates tool wear | Heat resistance, durability |

| Magnesium Alloy | Aerospace | Satellite Shells, Lightweight Frames | Flammability requires careful handling | Ultra-lightweight, corrosion-resistant |

| Inconel | Aerospace | Rocket Nozzles, Engine Components | Extreme toughness demands advanced tools | High-temperature performance |

Unlocking Precision: How CNC Machining Services Tackle Complex Materials

The magic of CNC machining services lies in their ability to tame even the toughest materials. Five-axis CNC machines, for instance, can sculpt a titanium turbine blade with curves and contours that traditional three-axis systems could only dream of. These machines use advanced software to optimize tool paths, ensuring every cut is precise and efficient. But it’s not just about hardware—artificial intelligence (AI) is transforming CNC machining by predicting tool wear, adjusting cutting speeds, and catching defects in real time. Studies show AI-driven CNC systems can reduce material waste by 20% and boost throughput by 15%.

Still, challenges remain. Advanced materials like titanium and Inconel chew through standard tools, driving up costs. For example, machining titanium can reduce tool life by 30% compared to aluminum. Then there’s the skills gap—only 40% of U.S. manufacturers report having enough skilled CNC operators to meet demand, according to a 2024 Deloitte study. The solution? Smarter tools and training. Polycrystalline diamond (PCD) tools and ceramic coatings extend tool life by up to 50%, while cross-training programs help workers master complex CNC systems.

Automation is another game-changer. Robotic arms now handle material loading and part inspection, letting CNC machining services run 24/7 with minimal human intervention. This is a big deal in 2025, as labor shortages push manufacturers to lean on tech to keep up with demand. By combining AI, automation, and advanced tools, CNC services are unlocking new levels of precision and efficiency.

See also: The Rise of Voice Technology: How Smart Assistants Are Changing Our Lives

Real-World Applications: CNC Machining Services in EV and Aerospace Success

Let’s get real—CNC machining services aren’t just theoretical. They’re powering tangible successes in EVs and aerospace. Take Tesla, which relies on CNC machining to craft aluminum battery housings for its Model Y. These housings must be lightweight yet robust, with tolerances under 0.01 mm to ensure battery safety. CNC machining delivers, using five-axis systems to shape complex surfaces in one go, cutting production time by 25% compared to multi-step processes.

In aerospace, companies like Boeing use CNC machining services to produce titanium turbine blades for their 787 Dreamliner. These blades endure temperatures above 1,200°C and require precision to within 0.005 inches. CNC machines, paired with AI-optimized tool paths, achieve this while minimizing waste. Another example: satellite manufacturers like SpaceX use CNC to machine magnesium alloy shells, balancing weight and durability for missions to Mars and beyond.

Table 2: Case Studies of CNC Machining Services in EV and Aerospace

| Company | Industry | Component | Material | CNC Machining Impact | Outcome |

| Tesla | EV | Battery Housing | Aluminum Alloy | Reduced production time by 25% | Improved EV range by 10% |

| Rivian | EV | Carbon Fiber Body Panels | Carbon Fiber | Enabled complex curves with 0.01 mm tolerance | Enhanced vehicle aesthetics, safety |

| Boeing | Aerospace | Turbine Blades | Titanium Alloy | Achieved 0.005-inch precision | Improved engine efficiency |

| SpaceX | Aerospace | Satellite Shells | Magnesium Alloy | Reduced weight by 15% | Lowered launch costs |

| Airbus | Aerospace | Structural Frames | Inconel | Minimized waste by 20% with AI optimization | Enhanced durability, reduced costs |

Sustainable CNC Machining Services: Paving the Way for Green Manufacturing

Sustainability isn’t just a buzzword—it’s a mandate. In 2025, CNC machining services are leading the charge toward green manufacturing. By optimizing nesting algorithms, CNC providers cut material waste by up to 10%—a big deal when you’re working with pricey carbon fiber. Energy-efficient CNC machines, equipped with high-efficiency motors and advanced cooling systems, slash power consumption by 20%. Some providers even recycle metal shavings, turning scrap into reusable raw materials.

This matters for EVs and aerospace, where sustainability is a competitive edge. Tesla, for instance, aims for net-zero emissions by 2030, and its suppliers are under pressure to follow suit. Aerospace firms face similar scrutiny, with regulations like the EU’s Green Deal pushing for lower carbon footprints. CNC machining services that prioritize sustainability—through waste reduction, energy efficiency, and recyclable materials—are winning contracts and building trust.

Table 3: Sustainability Metrics for CNC Machining Services

| Metric | Baseline (2020) | 2025 Achievement | Impact | Industry Benefit |

| Material Waste Reduction | 15% waste rate | 10% waste rate | 33% less scrap | Lower costs, eco-friendly production |

| Energy Consumption | 100 kWh/part | 80 kWh/part | 20% energy savings | Reduced carbon footprint |

| Tool Life Extension | 500 parts/tool | 750 parts/tool | 50% longer tool life with PCD coatings | Cost savings, less frequent replacements |

| Recycled Material Usage | 10% recycled | 25% recycled | 150% increase in recycled inputs | Supports circular economy |

| CO2 Emissions per Part | 50 kg CO2/part | 40 kg CO2/part | 20% lower emissions | Aligns with net-zero goals |

The Future of CNC Machining Services: AI, Robotics, and Beyond

The future of CNC machining services is bright—and high-tech. AI is already making waves, with predictive maintenance cutting downtime by 30%, according to a 2024 McKinsey report. Robotics are taking it further, automating repetitive tasks like part loading and quality checks, boosting productivity by 15%. Looking ahead, hybrid manufacturing—combining CNC machining with 3D printing—promises to revolutionize rapid prototyping. Imagine an EV startup designing a new battery case, using 3D printing for initial shapes and CNC machining for final precision, all in days instead of weeks.

Local production is another trend to watch. With global supply chains still shaky in 2025, thanks to geopolitical tensions, CNC machining services are seeing a surge in demand for local manufacturing. In the U.S., the 2024 American Manufacturing Act offers tax breaks for domestic production, fueling a 15% rise in local CNC contracts. This “reshoring” trend not only cuts lead times but also reduces carbon emissions from shipping—a win-win for businesses and the planet.

Actionable Strategies for Leveraging CNC Machining Services in 2025

So, how can businesses make the most of CNC machining services? For CNC providers, the path is clear: invest in five-axis machines and AI-driven software to handle advanced materials like titanium and carbon fiber. Adopt sustainable practices, like energy-efficient equipment and material recycling, to attract eco-conscious clients. Partner with technical colleges to train the next generation of CNC operators, addressing the skills gap head-on.

For EV and aerospace companies, choosing the right CNC partner is key. Look for providers with expertise in advanced materials and a track record of precision—check their case studies, like those for Tesla or Boeing. Prioritize local CNC services to minimize supply chain risks, especially in volatile markets. And don’t shy away from hybrid manufacturing options, which can slash prototyping costs by 20%.

Conclusion: Powering the Future with CNC Machining Services

CNC machining services are more than just a manufacturing tool—they’re a catalyst for innovation. By mastering advanced materials, embracing AI and automation, and prioritizing sustainability, these services are meeting the soaring demands of the EV and aerospace industries. From lightweight battery housings to high-strength turbine blades, CNC machining is shaping the technologies that move us forward. As we race toward a greener, faster, and more connected future, one thing is clear: CNC machining services are the precision engine driving it all.

FAQ:

1. What are CNC machining services, and why are they vital for EVs and aerospace?

CNC machining services use computer-controlled tools to shape materials like titanium, carbon fiber, and aluminum with extreme precision—down to 0.001 inches. For electric vehicles, they craft lightweight battery housings that boost range by up to 15%. In aerospace, they produce turbine blades that withstand 1,200°C heat. These industries rely on CNC’s ability to handle complex materials and tight tolerances, ensuring parts are both functional and reliable. Without CNC machining, the intricate components driving Tesla’s efficiency or Boeing’s safety wouldn’t exist.

2. How do CNC machining services process tough materials like titanium and carbon fiber?

Titanium and carbon fiber are no walk in the park—titanium’s hardness chews through tools, and carbon fiber can crack if mishandled. CNC machining services tackle this with five-axis machines that carve complex shapes in one go and specialized tools like polycrystalline diamond (PCD) that last 50% longer. AI steps in to optimize cutting paths, slashing waste by 20%. This combo lets manufacturers create everything from EV motor casings to aerospace satellite shells with pinpoint accuracy.

3. Why is sustainability a big deal for CNC machining services in these industries?

Sustainability isn’t just a trend—it’s a game-changer. CNC machining services cut material waste by 10% using smart nesting algorithms and reduce energy use by 20% with efficient machines. They also recycle metal scraps, aligning with goals like Tesla’s 2030 net-zero target. For EV and aerospace companies, choosing sustainable CNC providers means lower costs and a smaller carbon footprint, which is critical as regulations like the EU’s Green Deal tighten.

4. How do AI and automation make CNC machining services better?

AI is like a brain boost for CNC machining—it predicts tool wear, catches defects, and optimizes cuts, boosting efficiency by 15% and cutting downtime by 30%, per a 2024 McKinsey report. Automation, like robotic arms handling parts, keeps production running 24/7. This is huge for crafting complex EV battery components or aerospace frames, where precision and speed are non-negotiable. Together, they make CNC services faster, smarter, and more reliable.

5. What challenges do CNC machining services face with advanced materials?

Advanced materials like titanium wear out tools 30% faster than aluminum, hiking costs. Carbon fiber’s brittleness demands specialized tools to avoid cracks. Plus, there’s a skills crunch—60% of manufacturers lack enough trained CNC operators, according to Deloitte’s 2024 study. The fix? High-durability PCD tools and cross-training programs to build expertise. These solutions keep CNC services competitive despite the tough demands of EV and aerospace manufacturing.

6. How should EV and aerospace companies pick a CNC machining service provider?

Choose a CNC provider with a track record in advanced materials—think Tesla’s battery housings or Boeing’s turbine blades. Look for companies using five-axis machines and AI-driven systems for top precision. Local providers are a smart bet in 2025’s shaky supply chain world, cutting lead times and risks. Also, prioritize those with sustainable practices, like recycling or energy-efficient setups, to align with industry green goals and save costs.